Getting Professional Outcomes With Ceramic Spray Finishing: Proven Strategies and Best Practices Disclosed

As experts in the field of vehicle detailing and surface defense are constantly seeking ways to boost the high quality of their job, the application of ceramic spray layers has arised as a game-changer. The appeal of attaining a remarkable, long-lasting completed with marginal initiative is obvious. Nonetheless, the course to grasping this method is paved with nuances and ins and outs that require attention. Recognizing the important devices, surface area prep work techniques, accurate application methods, and upkeep approaches are key components in the pursuit for professional-grade results. By discovering the tested strategies and best techniques behind ceramic spray layer, a world of possibilities opens for those wanting to boost their craft and provide impressive coatings.

Advantages of Ceramic Spray Layer

The benefits of using ceramic spray coating in numerous applications are well-documented and widely recognized in the automobile and industrial industries. Ceramic spray layers use remarkable defense versus ecological pollutants, UV rays, chemicals, and oxidation, providing a long lasting guard for surface areas.

Additionally, ceramic spray layers create a hydrophobic surface that fends off water and protects against water spots, making cleaning and maintenance simpler and much less lengthy. The enhanced gloss and deepness of color supplied by ceramic finishings can offer vehicles and industrial tools a showroom finish that lasts. Moreover, the scratch-resistant residential or commercial properties of ceramic coatings aid keep the visual appeal of surfaces in time, contributing to the overall value and long life of the layered items. To conclude, the benefits of ceramic spray layer make it a preferred choice for securing and improving surface areas in a selection of applications.

Vital Tools and Products

Having actually understood the advantages of ceramic spray covering, it is necessary to detail the vital tools and products required for its effective application in various industries. To attain specialist results, the adhering to devices and products are important:

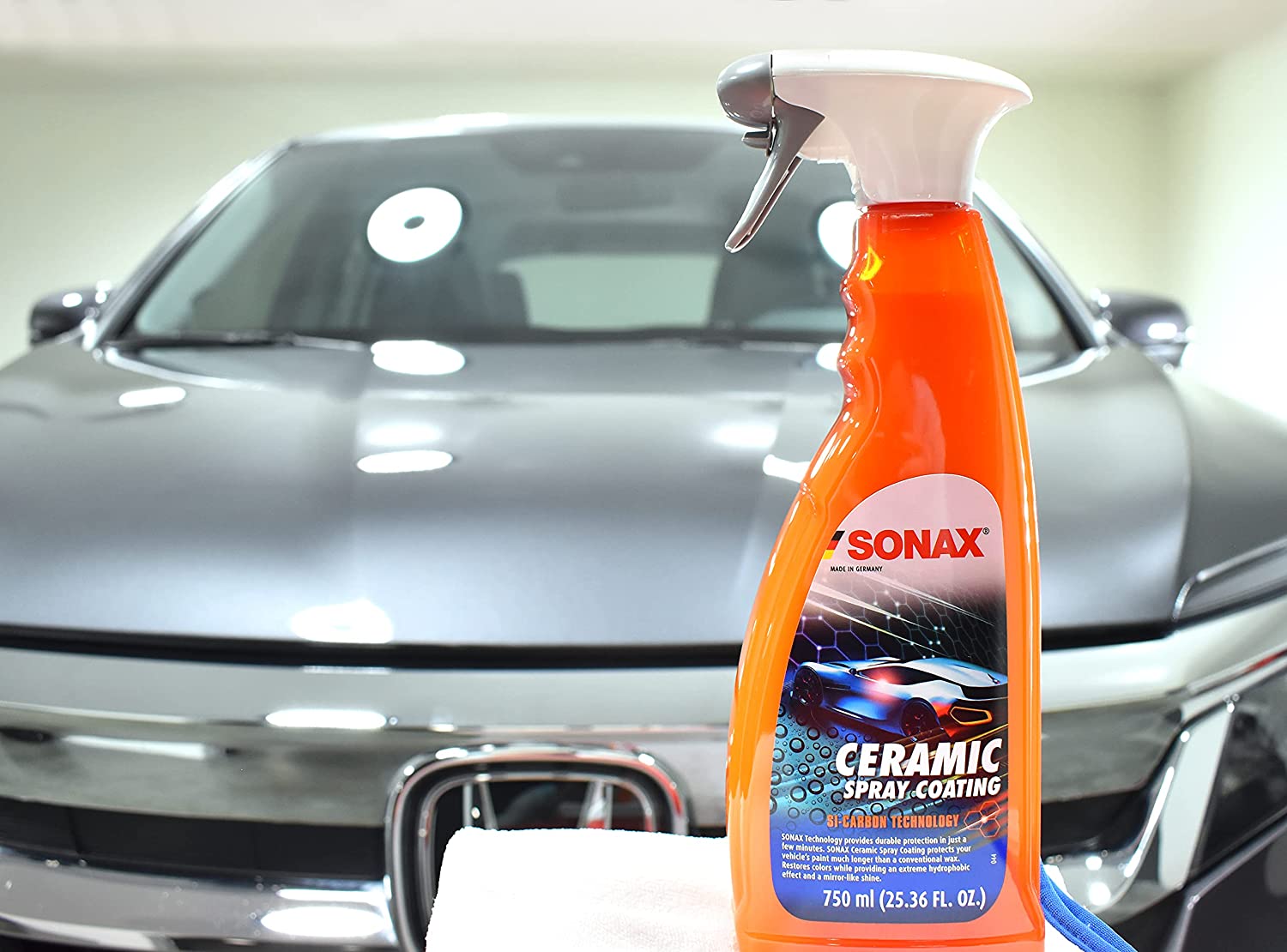

Ceramic Spray Covering: The heart of the process, the ceramic spray finish itself provides the safety layer that improves longevity and visual appeals. - ceramic spray coating

Microfiber Towels: Made use of for cleaning down the surface area prior to applying the ceramic spray coating and for buffing off excess item after application.

Spray Bottles: Crucial for evenly dispersing the ceramic covering onto the surface area.

Protective Equipment: Handwear covers and masks to make certain safety and security throughout the application procedure.

Polishing Compound: For preparing the surface by getting rid of any kind of flaws prior to using the ceramic finishing.

Clay Bar: Helps in decontaminating the surface area by removing ingrained particles, making certain a smooth application.

Application Pads or Applicators: Made use of for equally spreading the ceramic spray layer onto the surface area.

Appropriate Surface Prep Work Techniques

Effective surface area preparation is essential to guaranteeing the successful application of ceramic spray layer in different sectors. To attain optimum outcomes with ceramic spray finish, proper surface area preparation strategies should be employed.

The very first step in surface prep work is complete cleansing. ceramic spray coating. Any kind of dirt, residue, wax, or grease have to be entirely removed from the surface to ensure appropriate adhesion of the ceramic finishing. This can this contact form be done making use of a mild detergent or a dedicated surface area cleaner

Following, the surface area must be polished to eliminate any flaws such as swirl marks or scrapes. This action not just enhances the look of the surface area yet also makes certain a smooth and even application of the ceramic coating.

Application Tips for Ideal Outcomes

To make sure remarkable results with ceramic spray finishing, meticulous attention to application techniques is paramount following the careful surface area preparation procedures. When using ceramic spray covering, it is critical to operate in a regulated atmosphere cost-free from straight sunshine or solid winds. Optimum application conditions normally consist of moderate temperature levels and reduced humidity levels to promote correct healing and bonding of the finish to the surface.

Previous to application, shake the ceramic spray coating bottle intensely to ensure the formula is well combined. It is important to work in little sections to YOURURL.com guarantee complete application and stop the layer from drying too soon.

After applying the ceramic spray layer, allow sufficient time for it to cure according to the maker's directions. As soon as healed, make use of a high quality microfiber towel to gently buff the surface area to a high gloss finish. By adhering to these application suggestions diligently, you can achieve ideal outcomes and optimize the safety advantages of ceramic spray finishing.

Maintenance and Durability Methods

Maintaining the longevity and safety top qualities of ceramic spray covering requires constant and systematic upkeep methods. To make sure the finishing continues to be efficient, regular washing with a pH-neutral auto shampoo is vital.

Regular assessment of the covering is additionally important for determining any kind of locations that might need touch-ups or reapplication. This can be done by carrying out a straightforward water beading test or aesthetically examining the surface for any kind of signs of wear. Addressing any problems without delay can help preserve the covering's protective buildings and extend its life expectancy.

In addition, preventing rough chemicals, rough cleansers, and automated cars and truck cleans can aid protect the integrity of the ceramic spray finishing. By following these upkeep methods, experts can guarantee their ceramic-coated cars preserve a high level of protection and aesthetic charm for a prolonged period.

Conclusion

Finally, accomplishing expert outcomes with ceramic spray layer requires mindful factor to consider of crucial tools and products, appropriate surface preparation strategies, and application tips for optimum results. By complying with proven techniques and ideal practices, upkeep and durability of the covering can be made best use of. It is very important to abide by these standards in order to attain the wanted expert have a peek at this site results and guarantee the performance of the ceramic spray layer.

As professionals in the field of vehicle outlining and surface protection are constantly seeking ways to elevate the top quality of their job, the application of ceramic spray coatings has emerged as a game-changer.Additionally, ceramic spray finishings create a hydrophobic surface that wards off water and stops water areas, making cleansing and upkeep easier and less time-consuming. In final thought, the benefits of ceramic spray covering make it a preferred choice for protecting and boosting surface areas in a selection of applications.

To make sure outstanding end results with ceramic spray coating, meticulous attention to application techniques is paramount adhering to the thorough surface area preparation treatments.In verdict, accomplishing expert results with ceramic spray finishing needs cautious factor to consider of important devices and materials, proper surface area prep work methods, and application suggestions for optimal outcomes.

Comments on “Why Choose Ceramic Spray Coating: Superior Shield for Your Car's End up”